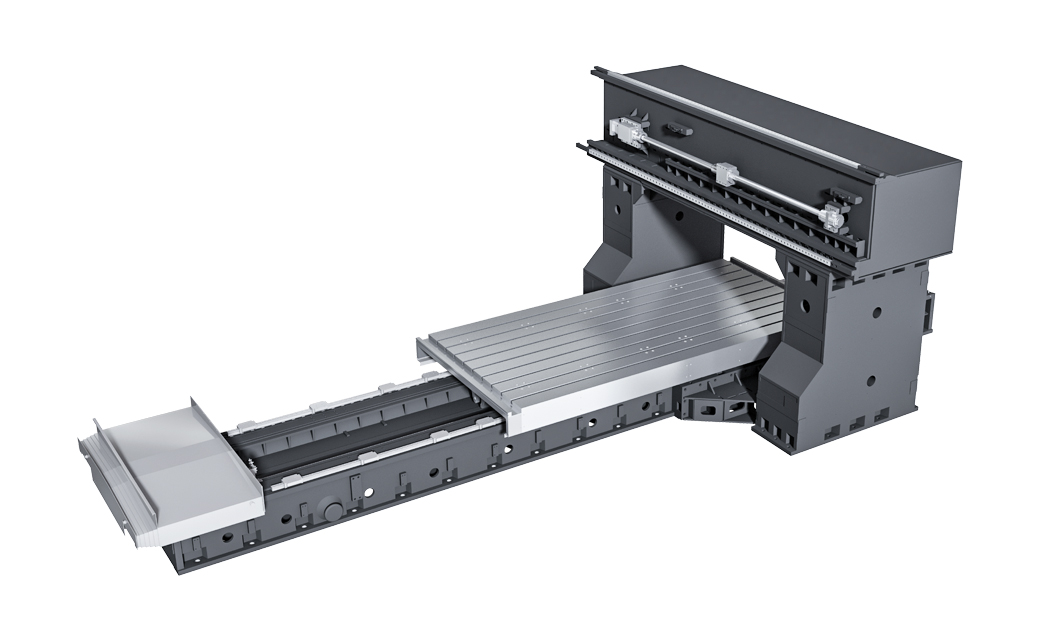

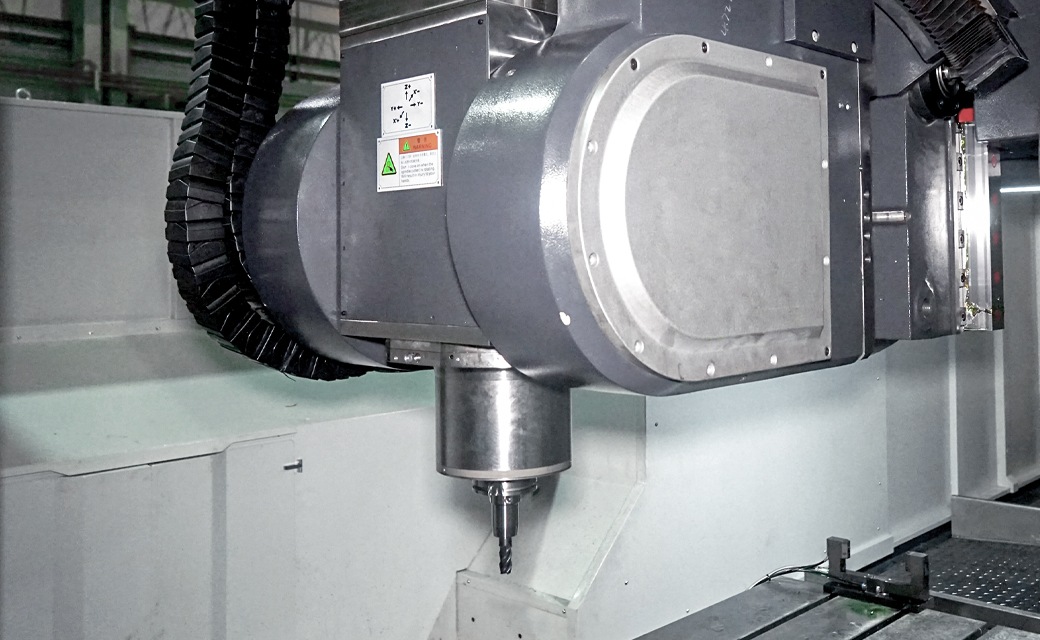

Five-axis high-speed milling center featuring A/B-axis design, fixed beam, and moving table structure. Optimized for complex metal parts, especially titanium alloy components. Primarily used in aerospace and high-speed railway industries.

Direct Contact

No matter where you are – our regional sales & service partners are available to answer all your questions.