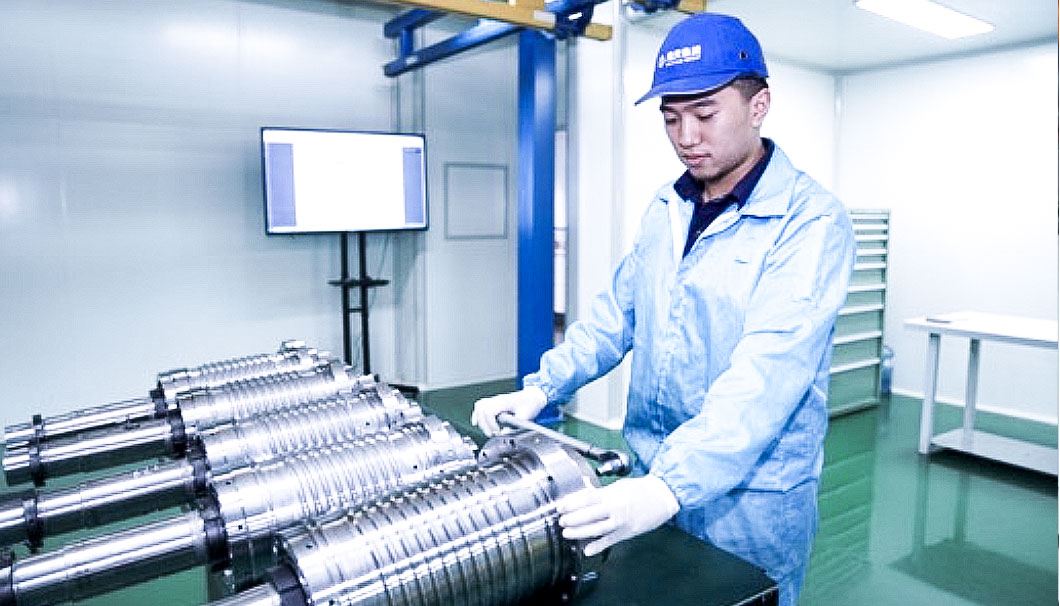

With deep manufacturing expertise, Haitian Precision ensures 100% in-house production of core components. Advanced processing machines guarantee maximum precision, efficiency, and reliability – delivering top-tier quality for high-performance industrial applications.

Percent manufacturing depth

Components produced in-house

Production area | sqm

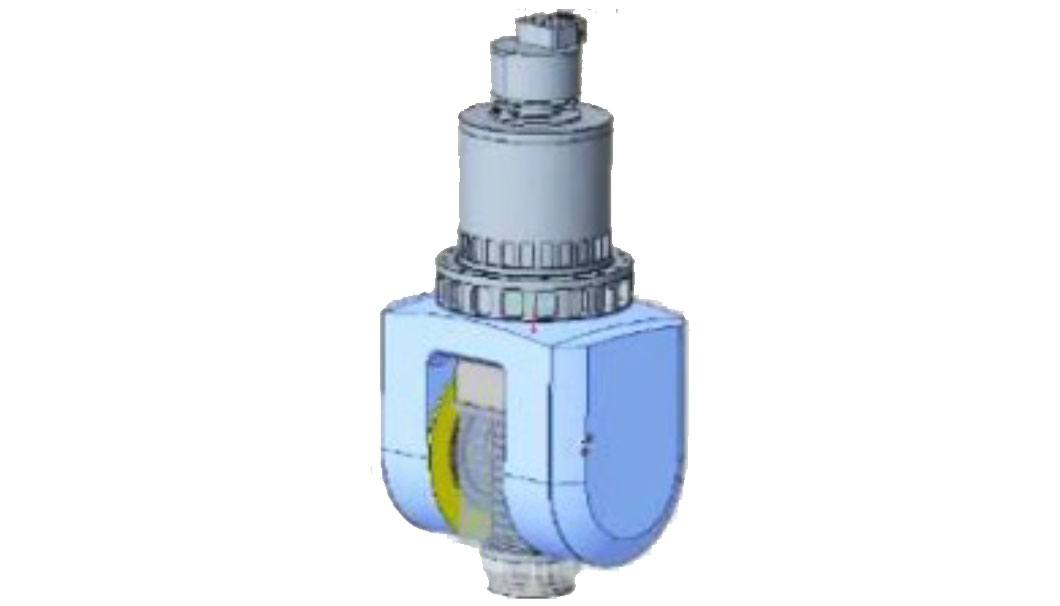

Multi-patented spindles

µm accuracy measurement

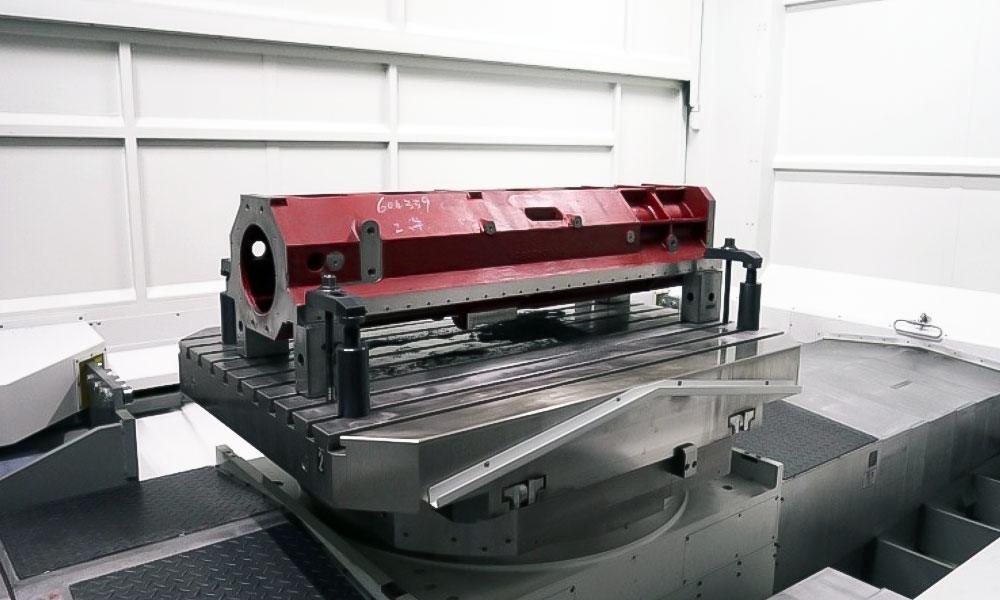

Automated Production Line

Our fully automated production system integrates AGVs, robotic assembly, and smart logistics to ensure maximum efficiency and cost savings. With seamless ERP, MES, and DNC system connectivity, we reduce manual intervention and optimize manufacturing output.

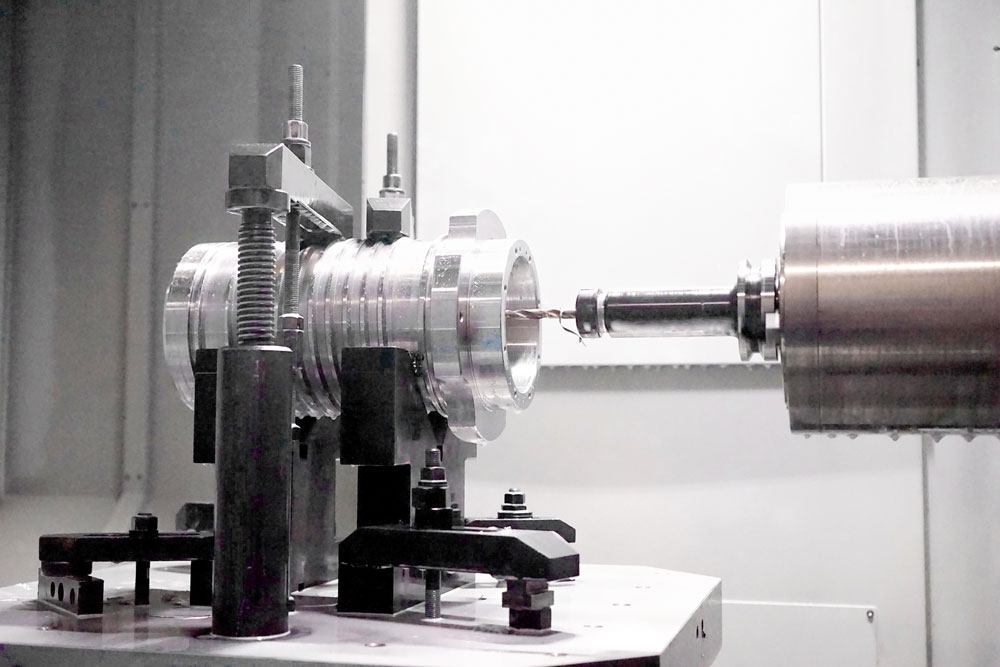

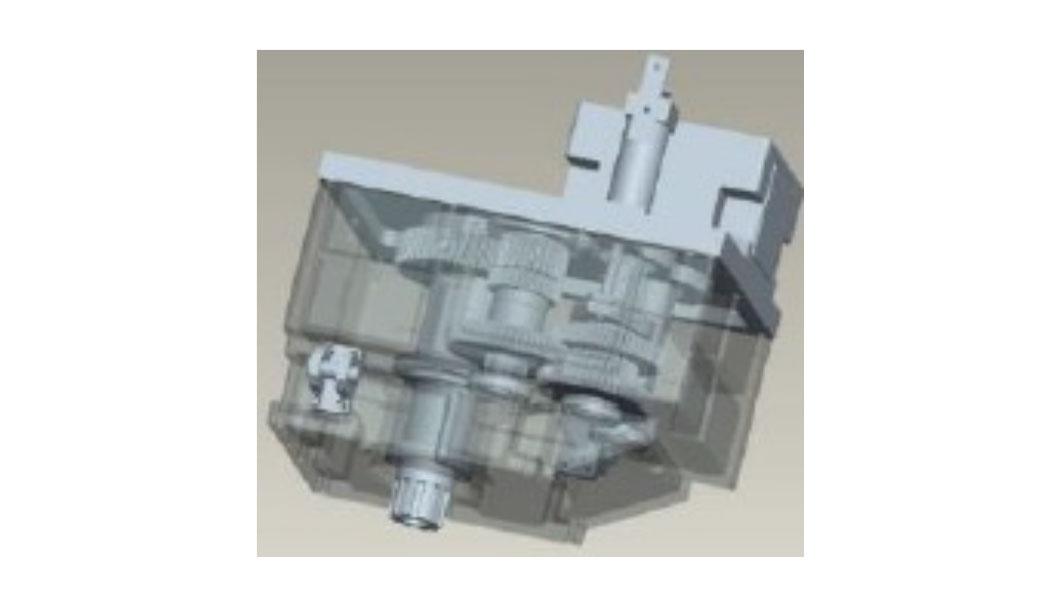

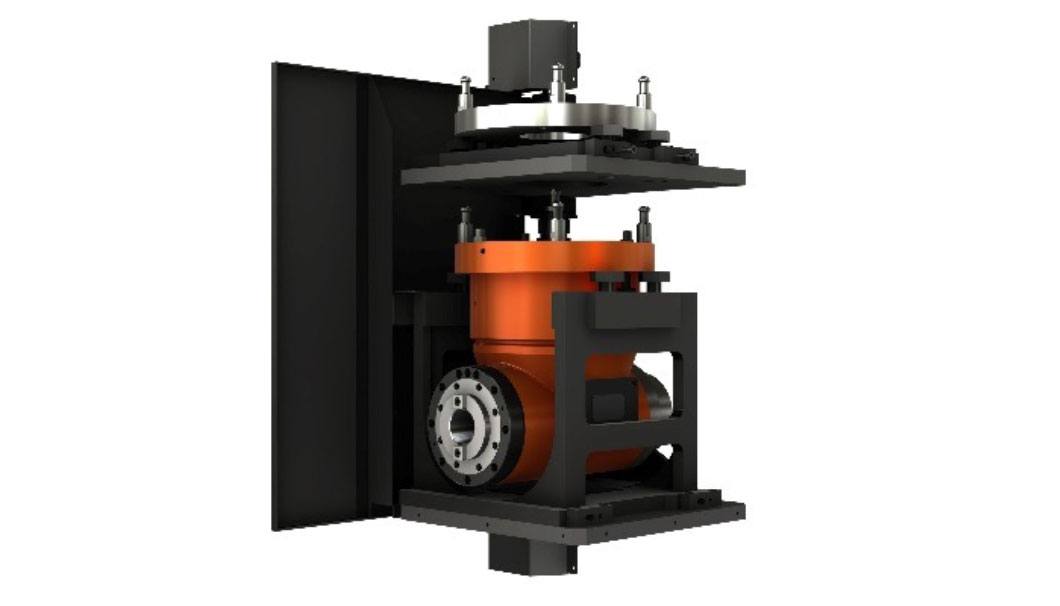

Advanced Technologies

State-of-the-art machining centers ensure maximum precision and efficiency. With advanced HMC and grinding technologies, we achieve ultra-accurate processing of core components, guaranteeing long-term stability, superior surface quality, and optimized production performance.

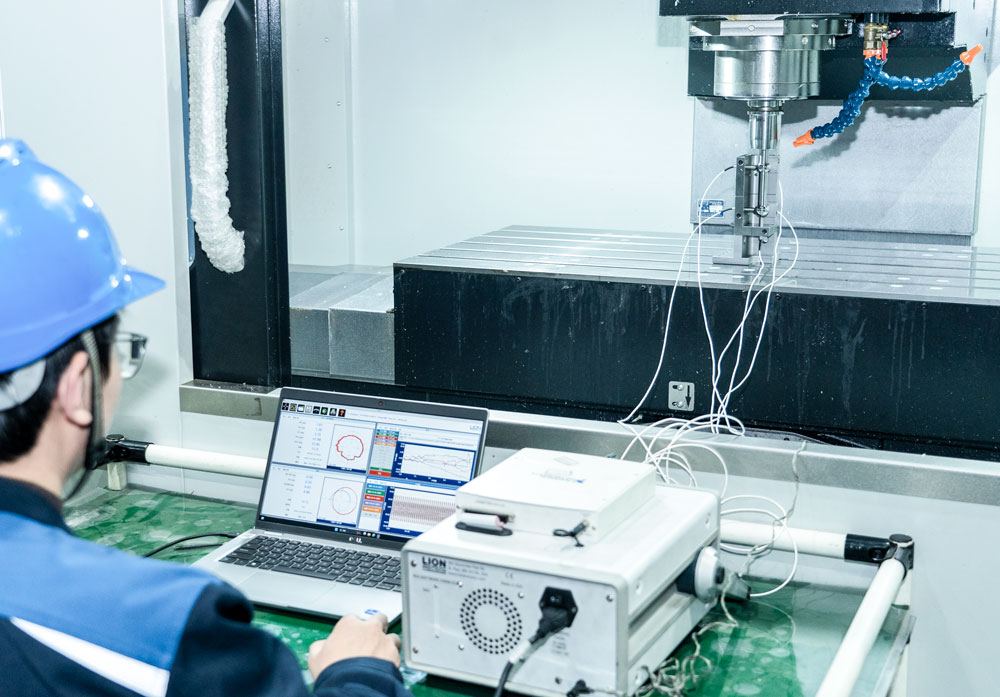

Precision Testing

With 0.6 μm precision measurement, our advanced testing ensures maximum accuracy and long-term stability. From thermal compensation to laser detection, each component undergoes rigorous quality control to guarantee the highest machining performance.

Key Processes – Precision in Every Component

Precision Testing – Quality You Can Measure

With 0.6µm accuracy measurement, thermal compensation, and laser detection, we ensure the highest precision in CNC manufacturing.